Recycling of Mineral Wool Waste

Authors: Katharina Grass, Victor Bartashov, Jurgen

Sucker

IB Engineering GmbH, Vienna, Austria

19.03.2021

Mineral wool waste in Europe accounts for 20 to 60% of

the production volume. In practice, this means 160,000 to 480,000 tons of waste

from 40 production lines, in average 20,000 t/a per line. [2]. Considering that

the yearly increase of industrial production, the volume of stored waste is

constantly growing. Expenses for removal and disposal of industrial mineral

waste are immensely high (on the average, 8–10% of the value of manufactured

products [3]).

1.

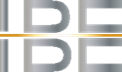

Types and sources of mineral wool waste

The major sources of mineral wool

waste are listed below:

- mineral

wool industry,

- construction

and demolition sector,

- technical

insulation,

- substrate

for growing plants.

The production of mineral wool insulation

accumulates a large amount of industrial waste at different stages of

production process:

- waste at the stage of

raw material preparation (screening),

- waste of melting unit

(cupola dust, cupola slag),

- waste of fiberizing

unit (shots, slag, large fibers),

- cutting waste

(cuttings and dust) and

Fig. 1: Types and sources of mineral wool waste

Additionally, in accordance with the Commission

Directive 97/69 / in EU, mineral wool is classified according to the degree of

carcinogenic danger in the so-called "old" and "new"

mineral wool.

Primarily, this concerns the return of used mineral

wool products (construction and demolition sector, technical insulation, etc.).

Since 2000, Europe has banned the production and use of biopersistent

mineral fibers. Thus, for “old” mineral wool produced before 2000, stricter

disposal rules are applied. Due to its carcinogenic effect, “old” mineral wool

cannot be recycled in mineral wool production.

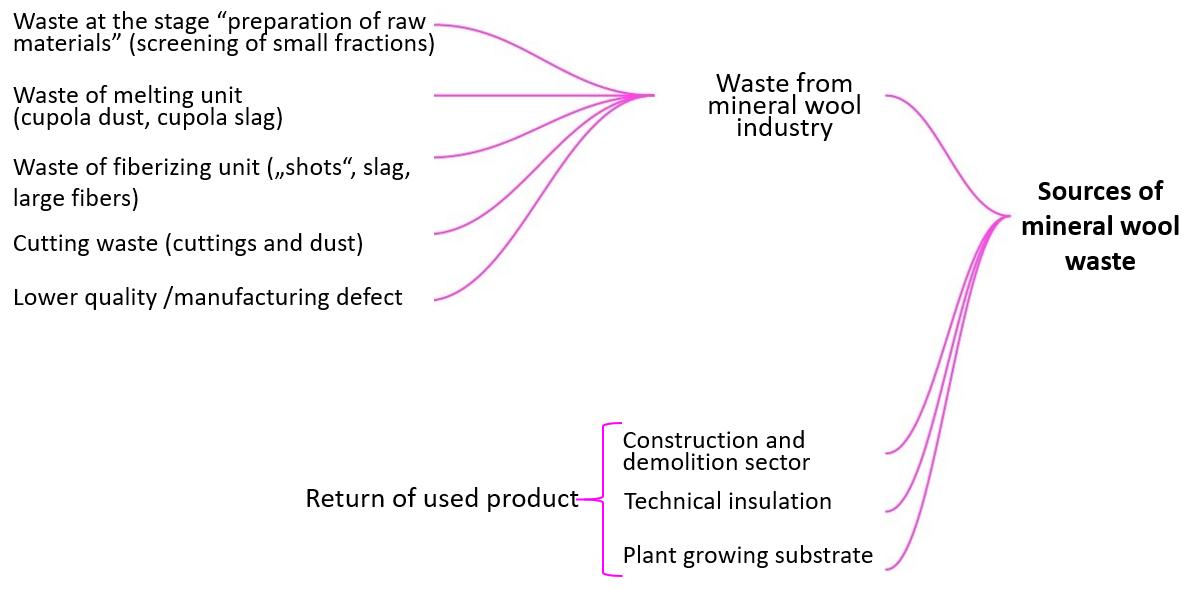

2. Handling of mineral wool waste

Currently three main directions of the subsequent use

of mineral wool waste can be specified: landfill, recycling in mineral wool

production and use in other industries.

Fig. 2: Main directions of mineral wool waste handling

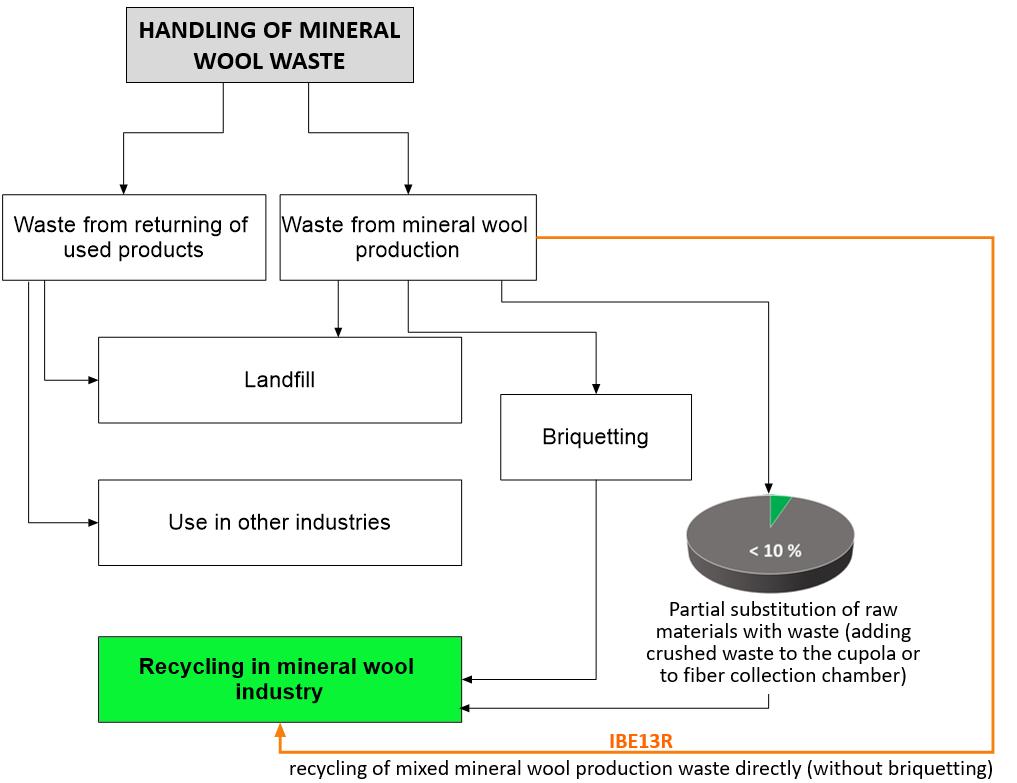

2.1. Landfill

Landfill is the

easiest way in the practice of waste handling, though it has several

disadvantages. For manufacturers of mineral wool products, these are, on the

one hand, the loss of valuable raw materials that can be used in manufacturing

a new insulating product, thus gaining profit (see Fig. 3).

Fig. 3: Material losses from waste in the production

of mineral wool insulation materials

On the other hand, abstaining form waste recycling causes high additional costs for disposal and transport.

The expenditures for the landfill of mineral wool waste in recent years has

increased significantly in several countries. For example, the landfill fee, a

few years ago in Germany amounted to 40 / 50 euros per ton. At present, the

costs for waste disposal on landfills is approx. 225 euros / t [4].

Furthermore, inefficient use of non-renewable, easily accessible natural

resources (basalt, dolomite, etc.) leads to their rapid depletion, as well as

to accumulation of a large amount of waste. The latter, in turn, creates an environmental problem, having a negative

impact on soil, surface- and underground water and occupying vacant land areas.

Depositing mineral wool waste is technically difficult due to its large

volume, low bulk density, high elasticity, poor compressibility and,

consequently, lack of stability at the landfill [5].

2.2. Possibilities of using mineral wool waste in other

industries

When solving the issue of disposal of

"old" mineral wool, numerous attempts were made to use mineral wool

waste in other industries. Existing research on this topic emphasizes the applications in which potentially carcinogenic fibers are

destroyed or reliably bound. Scientific studies have been done on the use of mineral wool

waste in following areas:

- in cement industry [6], [7], [8],

- in production of ceramics, including building ceramics [3], [9],

[10],

- in wood-based

composites in combination with wood waste [11], [12],

- for backfilling in the mining industry [13],

- as a filler in composites based on cement or gypsum [14], [15].

- in the production of refractory concrete [16].

The difficulties in introducing these applications consist in the absence of proven technologies and the

necessary equipment, as well as in the imperfection of the waste management

system, including the organization of collection, sorting

and preparation of waste.

2.3. Recycling of waste in mineral wool industry

From the point of view of a circular economy, the

return of waste back to mineral wool production is the best solution, occupying

the second place in waste management hierarchy after waste prevention [17]. Remelting of mineral wool waste modifies such hazardous characteristics as morphology and

chemistry during melting and solidification process [18]. In addition,

replacing primary raw materials with secondary ones reduces the energy

consumption for smelting, thus making the process more economical.

One of the difficulties in reprocessing of mineral

wool waste is, however, a high content of small waste,

such as dust or shots. In the standard technology including cupola

furnace, lump raw materials with a size of about 100 mm are used. Feeding a

large amount of small waste can lead to blockage of air supply [18].

Therefore, the most common way to return small

waste back to the cupola furnace is the preliminary formation of briquettes

[19]. When briquetting, the waste is ground to a

homogeneous mass, mixed with cement and water, then formed into briquettes in a

hydraulic press, dried in a drying chamber and reused in the process of

producing mineral boards as one of the charge components [20].

Theis method, however, presents certain problems.

At high temperature the briquettes bound with cement split into small pieces

before the melting process starts, thereby making remelting in the cupola

furnace impossible because of the interrupted feeding of air and gases [21].

Furthermore, the melting of briquettes containing cement causes more significant

emissions of solid particles and sulfur oxides into the atmosphere than the

melting of virgin rock [2]. Hydraulic binders based on clay and liquid glass

are also not optimal for briquetting, because the strength of such briquettes

decreases at a temperature of about 500°C [1]. Briquettes containing clay-based binder have poor

moisture resistance and tend to absorb water and break down during storage

[22].

From the industrial point of view, briquetting is a

costly, intermediate process that requires additional material, energy, and

human resources.

In the framework a research program one of European

companies has developed a method for feeding mineral wool waste obtained in a

centrifuge and crushed to a fraction of 0–6 mm directly into a cupola furnace

[2]. With this method, a maximum of 10% substitution of the virgin rock can

be achieved.

Another known equipment for recycling of mineral

wool waste is focusing exceptionally on waste from edge trimmings and

manufacturing defect. Here the crushed waste is partially added to the product

in the fiber collecting chamber [23]. Same as in the previous method, the percentage of substitution of the

primary raw material is limited, so this option cannot be used for a large

amount of waste.

Summarizing the topic of recycling mineral wool

waste and its use in manufacturing of mineral wool products, the following

conclusions can be drawn:

- currently, there is no

possibility of processing mixed waste: none of the methods is designed to

process all types of industrial waste. Even with briquetting, it is

impossible to achieve the complete disposal of all waste.

- There is no

possibility of processing a large amount of waste directly, without

briquetting. The partially feeding of waste into

cupola furnace or fiber collecting chamber can enable to recycle only a

very small percentage of waste.

Finally, it should be noted that all known methods of

reusing the waste in production are currently applicable mainly to industrial

waste, the chemical composition of which is known. Thus, a few mineral wool manufacturers recycle exclusively the used

mineral wool insulation of own production [24]. The composition and condition of mineral insulation waste removed during

the demolition or renovation of buildings, are, in most cases, unknown [1]. Therefore, due to strict requirements to chemical composition of mineral wool in the European Union, the reusing

of such waste in production is currently considered unacceptable (see paragraph

1 and Fig. 2).

A few companies outside the European Union do not strictly divide mineral wool in "old" and "new", offering the

disposal of old mineral wool from construction site [25].

3. Conclusion: the main

reasons of irrational use of mineral wool waste

Regarding the above analysis, it can be concluded

that one of the main reasons for the irrational use of industrial mineral wool

waste is the lack of technologies and equipment that would allow to process

a wide range of waste at minimal cost.

Our company has approached this challenge by

developing an innovative technological solution. The technological line IBE13R designed by IB Engineering GmbH

allows to recycle a wide range of mineral wool waste at minimal cost, while

meeting the high requirements of resource efficiency and environmental

protection (link: EQUIPMENT AND

TECHNOLOGY FOR RECYCLING MINERAL WASTE)

References:

1

Väntsi O., Kärki T. (2014):

Mineral wool waste in Europe: a review of mineral wool waste quantity, quality,

and current recycling methods; Journal of Material Cycles and Waste Management,

Bd. 16, pp. 62-72.

2

Karppinen, K. (2002).: Paroc-WIM—Waste

injection into the stone wool melting furnace—LIFE02 ENV/FIN/000328, https://ec.europa.eu/environment/life/project/Projects/index.cfm?fuseaction=home.showFile&rep=laymanReport&fil=LIFE02_ENV_FIN_000328_LAYMAN.pdf, [Accessed:

02.02 2021].

3

Abdrakhimov V.Z. (2019): Use of mineral wool waste in the

production of ceramic wall materials, Samara State University of Economics, Vestnik PNGSPU. Construction and architecture, Samara,

Russia, https://www.researchgate.net/publication/342650277_THE_USE_OF_WASTE_MINERAL_WOOL_IN_THE_PRODUCTION_OF_CERAMIC_WALL_MATERIALS,

[Accessed:14.02.2021].

4

Vogdt А. et al. (2019):

LifeCycle KMF Optimierung der Stoffströme im Lebenszyklus von Bauprodukten aus

künstlichen Mineralfaserdämmstoffen, Fraunhofer IRB Verlag.

5

Sattler T. et al. (2020): Mineral wool waste in austria,

associated health aspects and recycling options, https://digital.detritusjournal.com/articles/mineral-wool-waste-in-austria-associated-health-aspects-and-recycling-options/285, [Accessed:

28.01.2021].

6

Yliniemi J. et al. (2019): Mineral wool waste-based geopolymers;

Fiber and Particle Engineering Research Unit, University of Oulu, Finland;

Saint-Gobain, Finland.

7

Sattler T., Vollprecht D. and Pomberger R.

(2020): Stoffliche Verwertung von Mineralwolleabfällen

in der Zement- und Mineralwolleindustrie, https://www.vivis.de/wp-content/uploads/2020/11/342-355_Sattler.pdf, [Accessed:11.02.2021].

8

Kubiliute R., Kaminskas R., Kazlauskaite A.

(2019): Mineral wool production waste as

an additive for Portland cement Department of Silicate Technology, Kaunas

University of Technology, Kaunas, Lithuania, http://iranarze.ir/wp-content/uploads/2018/06/E7895-IranArze.pdf,

[Accessed:14.02.2021].

9

Pranckeviceine, J.; Balkevicius, V.; Spokauskas, A. (2010): Investigation on properties of

sintered ceramics out of low-melting illite clay and

additive of fine-dispersed nepheline syenite. Medziagotyra,

pp. 231-235.

10

Kizinievič O. et al. (2014): Investigation of the usage of

centrifuging waste of mineral wool melt (CMWW), contaminated with phenol and

formaldehyde, in manufacturing of ceramic products, Waste Management 34(8), pp.

1488-1494.

11

Jetsu P., Vilkki M., Tiihonen I. (2020): Utilization of demolition wood and

mineral wool wastes in wood-plastic composites, Finland; detritus

-Multidisciplinary Journal for Waste Resources & Residues.

12

Maminski, M.; Krol, M.; Jaskolowski, W.; Borysiuk, P. (2011):

Wood-mineral wool hybrid particleboards. European Journal of Wood and Wood

Products, 69 iss. 2, pp. 337-339.

13

Gröper,

J.; Lack, D. (2016): Verfahren zur Verwertung von Dämmmaterialabfällen aus

Mineralwolle in Spezialbaustoffen. In: Pomberger, R.u.a. (Hrsg.): Tagungsband zur 13. Recy

& Depotech-Konferenz, Leoben: AVW (Eigenverlag),

pp. 161-166.

14

An Cheng, Wei-Ting Lin, Ran Huang (2011): Application of rock wool waste

in cement-based composites; Materials & Design; Volume 32, Issue 2,

pp.636-642.

15

Babaev D.D., Zavadko M.Yu., Petropavlovskaya V.B.

(2020): Solutions in the field of waste disposal from the production of basalt

fibers; magazine "ISSUES OF SUSTAINABLE DEVELOPMENT OF SOCIETY", pp .: 431-436, 2020. Federal State Budgetary Educational

Institution of Higher Education "Tver State

Technical University", Russia, Tver.

16

Stonys R.et al. (2016): Reuse of ultrafine mineral wool production

waste in the manufacture of refractory concrete, Research article, Journal of

Environmental Management 176, pp. 149-156.

17

WKO

Kreislaufwirtschaft:

https://www.wko.at/service/umwelt-energie/kreislaufwirtschaft.html, https://digital.detritusjournal.com/articles/mineral-wool-waste-in-austria-associated-health-aspects-and-recycling-options/285,

[Дата обращения: 28.01.2021]

18

Sattler T., Galler

R. Vollprecht

D. (2019): Entwicklung innovativer

Recyclingverfahren für Mineralwolleabfälle – Projekt RecyMin; BHM Berg- und Hüttenmännische

Monatshefte volume 164, pp. 552–556.

19

Vollprecht, D. et al. (2019):

Innovative Landfilling and Recycling of Mineral Wool Waste as Backfill

Material, in the Cement Industry and in the M ineral

Wool Industry; Mineralische Nebenprodukte

und Abfälle 6; pp. 480-492, https://www.vivis.de/wp-content/uploads/MNA6/2019_MNA_480-493_Vollprecht, [Accessed:

10.01.2021].

20

Kataev D. (2018): 10 years under quality mark; https://ksonline.ru/333966/10-let-pod-znakom-kachestva/, [Accessed: 14.01.2021].

21

BALKEVIČIU, et al.: Analysis of some properties of model system

from low-melting illite clay and fibrous mineral wool

waste; Institute of Thermal Insulation, Vilnius Gediminas Technical University,

https://materialsscience.pwr.edu.pl/bi/vol25no1/articles/ms_2006_036.pdf,

[Accessed: 14.01.2021].

22

PAROC GROUP (2002): EP0546000B2; Process for mineral wool production.

23

FAS Hansek GmbH & Co KG: Mineral wool

recycling equipment: http://basalt-online.ru/section-equipment/recycling-of-mineral-wool-is-a-sophisticated-tool-that-combines-increased-profits-and-environmental, [Accessed:11.02.2021].

24

Vogdt

F. et al. (2019): Leitfaden Recyclingpotential von Mineralwolle, TU Berlin,

https://www.irbnet.de/daten/rswb/19089008967.pdf, [Accessed:

03.02 2021].

25

TECHNONICOL NEWS; http://fasad-rus.ru/news_end_new.php?id=4409, [Accessed: 12.02.2021].