Potential of Induction Inline-melting

Technology of Mineral Raw Materials in Recycling of Dusty, Powdery and Sludge Waste

Authors:

Katharina Grass, Victor Bartashov

IB

Engineering GmbH, Vienna, Austria

12.09.2021

Introduction:

Target Setting and Possible Solutions

Companies

of different industries face the same issues while recycling dusty, powdery and

sludge waste:

·

high

costs for transport and landfilling,

·

strict

environmental standards for waste disposal and, as a result, a failure to

dispose of waste in its original form,

·

loss

of profit from metals recovered from waste.

Such

industries are, among others:

·

recycling

of zinc-containing filter dust from the steel industry,

·

recycling

of lithium-ion batteries,

·

recycling

of sludge from municipal sewage treatment plants,

·

recycling

of fly ash from waste incineration plants.

The list

could be continued.

In some

cases, the solution comes with reducing of waste volume and compliance with

environmental standards for disposal. In other cases, there is also a

possibility of making additional profit by recovering valuable metals.

1. Vitrification / Waste Inertization

(IBEwi)

In cases where the recovery of certain metals is

not economically justified, but strict environmental requirements apply, the

waste can be converted into an optimal product for disposal by vitrification.

Vitrification /

Inertization is a method of immobilizing оf toxic

substances (such

as heavy metals) by enclosing them in a stable matrix (e.g. in a silicate

matrix). Vitrification prevents harmful components from leaching out over time.

Consider an example of the immobilization of

toxic substances through vitrification of fly ash from waste incineration. When

waste is burned in incinerators, fly ash containing a large amount of dangerous

chemical compounds, including heavy metals, emerges. Some heavy metals are

volatile at higher temperatures (e.g. Hg, Cd, Pb). Due to their volatility,

these metals accumulate on fly ash in the form of water-soluble salts.

Landfilling of these ashes without pre-treatment would lead to soil and

groundwater contamination. A widely used method of cementing fly ash before

disposal reduces the immediate release of heavy metals and other toxic

substances into the soil but does not completely prevent it. These substances

enter the environment through gradual leaching. In the long run, cement is not

a reliable material for binding dangerous chemicals and heavy metals. Vitrification

is not only a reliable method to prevent toxic substances from leaching out,

but also allows to significantly (!) reduce the volume of waste. As a result,

the waste requires significantly less landfill space. The costs of landfill

disposal are reduced accordingly.

The vitrification process IBEwi patented

by our company takes place in the following sequence (example of fly ash):

The fly ash is first melted in an IBE inline induction

melting furnace. Melting is possible both in pure form and with the addition of

glass-forming components such as sand, sodium, etc. The melt leaking from the

opening of melting furnace undergoes dry

granulation. The resulting vitrified product (granulate) is chemically stable

and prevents a leaching of heavy metals.

Obtaining a glassy product (granulate) in some

cases is economically justified even for the purpose of reducing the waste

volume. An example hereof are companies that continuously use mineral wool

products but not produce mineral wool themselves (e.g. use of mineral wool for

hydroponic systems). After processing mineral wool waste to granules, its volume is reduced by 100 times, which significantly

lessens disposal costs.

2. Recovery of Metals

2.1. When Is It Profitable?

Theoretically, the recovery of metals is

possible in most cases of disposal of metal-containing dusty waste. For

example, it is basically possible to separate metals from

fly ash during waste incineration (see above), but the criterion for such an

operation is the expediency and profitability of this process. In this case,

the production of metals from fly ash is uneconomical due to different,

constantly changing composition of the burnt waste.

With a known composition of waste, the process

of obtaining metals from waste can be beneficial, if the prices for the resulting

chemical element are high enough. Many chemical elements are found in nature in

limited quantities. Thus, their prices, even with stable demand, will continue

to grow in the future. An increase in prices is also possible with an

increasing demand for a particular raw material in connection with the

development of a particular industrial sector. Thus, nickel prices are

increasing due to the growing demand for this metal on the part of manufacturers of lithium-ion batteries [1].

Fig. 1: Demand

for nickel, t / year

Source: Buchert M., Sutter J.: Stand und

Perspektiven des Recyclings von Lithium-Ionen-Batterien aus der

Elektromobilität. (Current status and prospects for recycling

lithium-ion batteries from electric vehicles)

Similar

trends are observed with lithium and cobalt. The graphs show the projected

demand for cobalt and lithium feedstocks through 2050.

Fig. 2:

Demand for cobalt, t / year

Source: Buchert M., Sutter J.: Stand und

Perspektiven des Recyclings von Lithium-Ionen-Batterien aus der

Elektromobilität. (Current status and prospects for recycling

lithium-ion batteries from electric vehicles)

Fig. 3:

Demand for lithium, t / year

Source: Buchert M., Sutter J.: Stand und Perspektiven

des Recyclings von Lithium-Ionen-Batterien aus der Elektromobilität. (Current

status and prospects for recycling lithium-ion batteries from electric

vehicles)

Another

valuable metal, the price of which has recently been steadily growing, is zinc.

In 2020, zinc reserves fell to their lowest level in the last 11 years. Back in

2013, the reserves of this metal at the LME[1]

reached 1.2 million t; gradually decreasing, they reached 256 thousand t in the

1st quarter of 2021 [2].

2.2. Metal Recovery Process of Company IB Engineering (IBEmr)

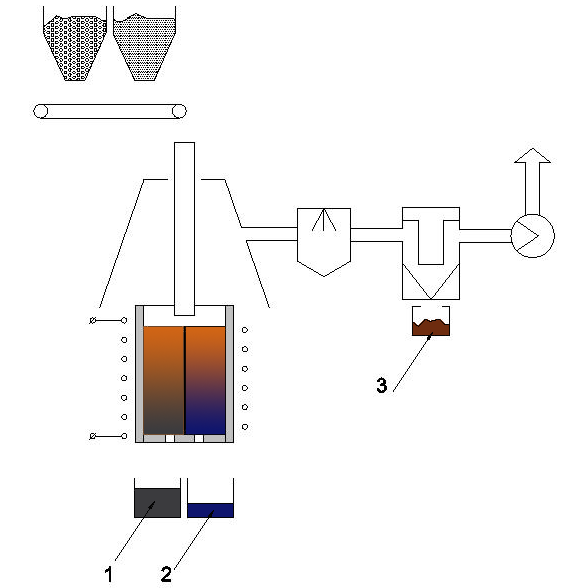

The

principle behind all IBE metal recovery technologies is basically the same and

includes:

·

high-temperature smelting of waste in an IBE inline induction

melting furnace,

·

separation

of the liquid metal phase from the phase of mineral melt,

·

evaporation

of metals, followed by rapid cooling, condensation and product collecting in

filters (Fig. 4).

1. mineral meltà slag 2. liquid metal phase 3. metal-containing filtrate.

Fig. 4: IBEmr: IBE technology used for metal recovery from

metal-containing waste

Slag can be

used, for example, in road construction, and profit could be made from obtained

metals.

2.3.

Examples of Metal Recovery from Industrial Waste

Some

examples of applications, where valuable metals can be recovered from dusty and

powdery industrial waste, are given below.

Utilization of zinc-containing filter dust of

metallurgical plants

Around 30% of global steel production were

achieved by melting steel scrap in an electric arc furnace (EAF). For every ton

of molten scrap, 15 to 22 kg of dust is generated, which is collected in

filters. This means that about 8.5 million tons of filter dust are produced

annually, containing 1.7 million t of zinc. Only around 45% of this dust worldwide

are recycled, and the rest is deposited in landfills. [3]

Currently, one of the most common methods of

recovering zinc from metallurgical EAF dust is the Waelz process (method of

recovering zinc from EAF dust in a rotary kiln). The disadvantages of the Waelz

process are: pelletizing with consumption of

slag formers, high fuel consumption, difficulties with temperature control; the Zn content in the dust must be at least

20%; iron and up to 5% zinc are lost

with slag.

IB Engineering offers an innovative

technological solution that corresponds to the above principle (Fig. 4):

Firstly, the metallurgical filter dust is

heated in an IBE induction melting furnace with the addition of a reducing

agent (e. g. carbon, in the form of broken coke). The reduced zinc vapor (at

oven temperature >950°C) is passing through the oxidation zone and cooling

zone and is collected as oxide in the filter. The slag is collected in a

container provided for this purpose and can be easily disposed of or used (e.

g. in road construction).

Recycling of lithium-ion batteries

On the one hand, storage and disposal of used

lithium-ion electric vehicle batteries entail a high risk of environmental

pollution and potential danger to human health due to the release of toxic

elements and gases. On the other hand, lithium-ion batteries are a valuable

resource, when properly recycled. For

example, a lithium-ion battery with a capacity of 50 kW*h, suitable for a range

of 250 to 300 km, contains about 10 kg of manganese, 11 kg of cobalt, 32 kg of

nickel and slightly more than 6 kg of lithium [4].

Currently, recycling lithium batteries in order

to recover valuable metals does not pay off for all the metals they contain.

Lithium, for example, is not economically recyclable. It is possible to extract

it from old lithium-ion batteries to save raw materials, but today it is

uneconomical [5]. According to experts' forecasts, the demand for lithium will

increase in the near future, and by 2050 it will already amount to more than

1,000,000 t/y (Fig. 3). This is primarily due to an increase in the future

production of electric vehicles.

The principle of the process is shown in the

diagram (Fig. 4) and described above. It is also applicable to the recycling of

lithium-ion vehicle batteries and the separation of valuable metals from them.

In this case, the preliminary stages of discharging, dismantling, mechanical

crushing and fraction separation take place before pyrometallurgical methods

are used.

3. Potential of Inline Induction Melting

in Recycling of Pulverized and Powdery Waste

Summarizing the above examples, it should be

noted that one of the important components of the IBE technological cycle is induction

melting. This applies to both the vitrification of waste and to more complex

process of recovering valuable metals from waste.

Melting of waste in the IBE technological cycle

takes place in a specially designed and patented induction furnace.

The

benefits of melting in an IBE inline induction furnace:

·

working

temperature up to 2500°С,

·

inline

process, i.e. continuous movement of charge through

tunnel from the starting material to the finished product,

·

the

ability to melt a wide range of material fractions from 0 to 10 mm,

·

the

possibility of obtaining three phases: two liquid phases (metallic and silicate

mineral phase) and a gaseous phase, which, being condensed, is captured in

filters.

In

addition, the IBE Inline induction furnace demonstrates the following

characteristics and potentials:

·

efficiency

>90%,

·

uniformity

of the melt temperature,

·

flexibility

(quick power on/off),

·

full

automation of the melting process; temperature control,

·

high

safety and comfortable working conditions for staff,

·

absence

of CO2 emissions.

For more

information, please visit our website https://www.ibe.at/en/

or contact us directly.

References:

[1] https://www.metalinfo.ru/ru/news/122016

[2] https://www.metalinfo.ru/ru/news/126391

[3] Curtis

S.: Sustainability in Action: Recovery of Zink from EAF Dust in the Steel

Industry, 2015 Intergalva Conference, Liverpool, England, 9th June 2015, http://www.icz.org.br/upfiles/arquivos/apresentacoes/intergalva-2015/5-2-Stewart.pdf

[4] https://www.jubatec.eu/recycling-von-lithium-ionen-akkus/

[5] https://futurezone.at/science/so-aufwendig-werden-alte-lithium-ionen-akkus-recycelt/401131764